How IIoT Can Optimize a Factory Floor

How IIoT Can Optimize a Factory Floor

IIoT applications on shop floors enable automated data collection and real-time tracking of crucial KPIs, such as workforce equipment availability, task allocation, and OEE. These applications help give visibility, identify areas of improvement, and make data-based decisions to optimize operational efficiency. Shop floor automation collects sensitive data from machines and labor, improves information accuracy, improves procedures regulation, and reduces sluggish onboarding and information loss.

How IIoT Can Optimize a Factory Floor

The manufacturing sector must constantly meet the demand of its ever-changing customers to remain competitive and strive. With the dynamically changing scope of the supply chain, the manufacturing industry is constantly looking up to Industrial Internet of Things (IIoT) based solutions for improvement in production efficiency and operations. Industrial IoT technology empowers the factory floor with visibility, automated data collection, real-time tracking of workforce equipment, and Overall Equipment Effectiveness (OEE) to enhance operations on the floor and improve productivity. Customized shop floor software, IoT devices with sensors, AI/ML.

What IIOT means for Factory Floor Industrial

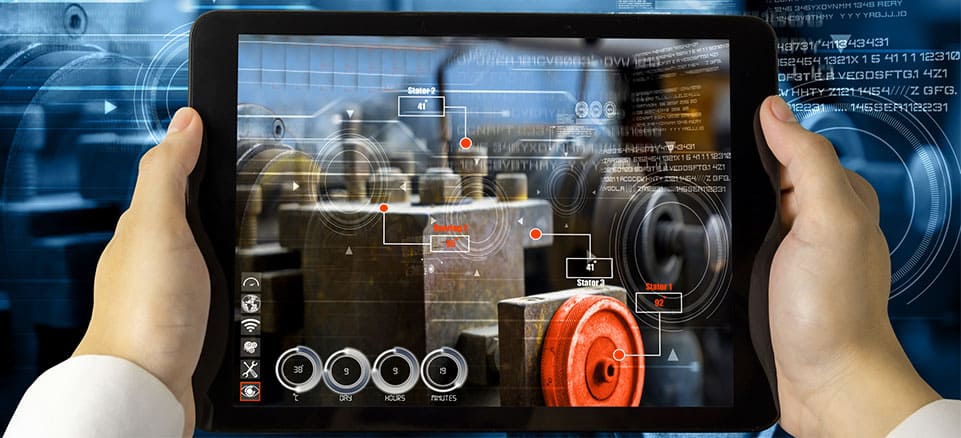

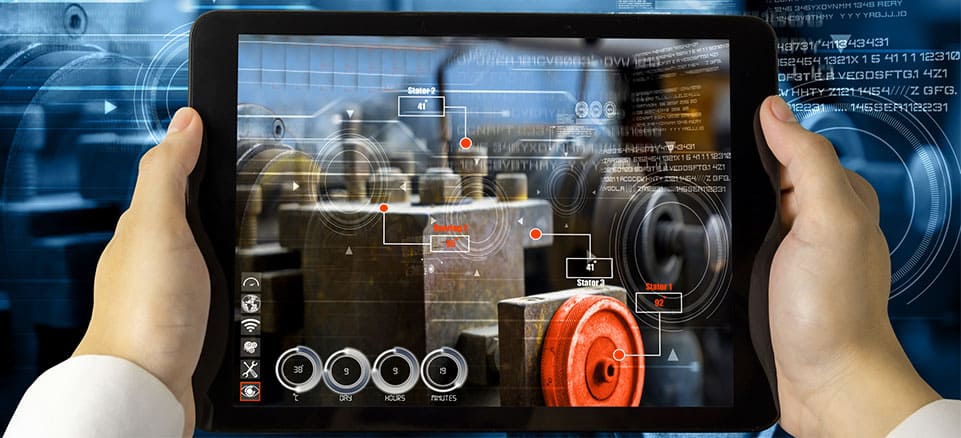

IIoT refers to the impact of IoT technology on industrial applications. IIoT connects people, physical world places, and machines with the digital world, like software, cloud platforms, automation, augmented reality, artificial intelligence, and data.

With the network of intelligent devices, IIoT monitor, collects, exchange, and analyze data, driving business decisions faster and more accurately. IIoT technology enhances manufacturing and industrial processes using smart sensors and actuators. Manufacturers are leveraging IIoT to attain their goal of a smart factory, i.e., a responsive, adaptive, and connected manufacturing. The shop floor of a manufacturing unit or factory is the most critical area where assembly and production get executed. It requires accurate data on activities, material status, machine, labor usage, resources, and workflow for improving operations.

How IIoT Optimizes a Factory Floor

The production process and workflow integrate machines, plants, and subassemblies from different manufacturers. The automatic monitoring of machine condition and productivity is difficult due to heterogeneity and entails high installation and maintenance costs, reducing efficiency and insufficient use of data

IIoT implementation helps develop and integrate a web-based software compatible with the existing system, sensors, and control system that can query and process all data on several machines. Available through the cloud or locally, we can link the software to the machine controller on an industrial PC and navigate through dashboards, providing respective users only relevant data.

Realtime Data Visualization

The factory floor of a manufacturing unit usually suffers from high particle concentration, affecting the functionality of machines, reducing product quality, and adversely affecting employees’ health. Smart IoT devices, consisting of embedded systems, sensors, and hardware, monitors particle and process by providing 24/7 real-time data. These devices can measure particles, and temperature and humidity sensors help record all environmental parameters. The recorded data gets analyzed in the cloud, and these devices easily connect to ERP, MES, or CAQ systems.

defined limits exceed, the device sends a notification via email or SMS. And dashboards help configure extensive reporting functions.Real-time data visualization by IoT devices assists the manufacturing environment meet production, quality, and labor standards.

Predictive Maintenance and Analytics

In any shop floor, machinery failure is the common incidence causing diversion in production and an increase in downtime and revenue or profitability implications. The use of IoT, sensors and analytics can predict and prevent catastrophic failure of plant machinery like CNC, boilers, compressors, etc.

IoT system equipped with sensors helps collect information on CNC operating status and performance. And the temperature and vibration sensors help detects increases in vibration or temperature. The central processing and analysis of data in real-time data help detect and resolve any issues before they become severe. An early warning system prevents faults, reduces machine downtime, and optimizes production.

Remote Monitoring

The machine operators must continuously determine the status of a machine to ensure efficient processes throughout the factory. Traditional tower lights can indicate the machine's status locally and provides visibility only when physically seen.

However, tower lights equipped with wireless communication technologies allow operators remotely monitor machine performance without the cable. The light indicates the machine status, and machine updates get transferred to a remote device through a secure wireless network. Machine operators can easily identify any operational problem and resolve it.

Benefits of IIoT Implementation on a Factory Floor

OEE Calculations

Data-driven decisions

Manage Safety

Improves Productivity

Empower Your Shop floor Operations with IIOT

Industrial IoT is revolutionizing the manufacturing process by leveraging data in meaningful ways. eLogicTech Edge, an IoT solution provider, helps deploy IoT and automate your shop floor to enhance safety and productivity. Our customized shop floor automation software, embedded hardware design, cloud integration services, and other IIoT solutions give visibility and identify areas of improvement.