The Hidden Cost of Hardware Prototyping

The Hidden Cost of Hardware Prototyping

Cost and Time Challenges

in Hardware Prototyping

Prototypes developed during a product life cycle, such as proof of concept, proof of product, proof of process, and production process, help validate and verify the design at each stage.

It brings numerous challenges to the designers and stakeholders; some are as follows.

1. Prototyping Cost

The cost of a prototype depends on the stage of the product development journey, i.e., concept design, design engineering, prototype, and testing or manufacturing, the risk involved at each stage helps determine the prototyping cost for each stage of development.

In a conceptual design, the risk involved is user confusion, physical size constraints, interaction methods, etc. The type of prototypes that can work is protoboard, development board etc. For this stage, low material costs are off the shelf and include 3D custom prototype parts, module electronics, and others.In a conceptual design, the risk involved is user confusion, physical size constraints, interaction methods, etc. The type of prototypes that can work is protoboard, development board etc. For this stage, low material costs are off the shelf and include 3D custom prototype parts, module electronics, and others.

For the design stage, scale models of products and hand-built models can be used to assess the signal integrity, EMI/EMC, wire and sub-component management, etc. Here, the cost of the prototype depends on the customized sub-system needed and user testing validation metrics.

2. Scope of Error of Prototyping

Improper product analysis can lead to some scope of error in the final product design. A developer may concentrate on a specific prototype, ignoring the proper analysis of the entire project and overlooking effective solutions with incomplete details.

Other factors that may lead to scope-of-error in prototyping are not setting realistic, measurable, specific, achievable, and time-sensitive goals. Testing a prototype, unfinished or at a lower fidelity stage, doesn’t resemble the final product closely enough. And when it’s too fit, time is spent perfecting one version instead of getting feedback.

3. Limitations in the Number of Iterations

Iteration is the sequential testing and refinement of a prototype. It is a primary technique that leads to the gradual achievement of requirements and determines the appropriate component, size, shape, architecture, and performance improvement. Iteration is essential to meet challenging requirements, get insight into issues, identify errors and simplify parts. It leads to self-efficacy and design requirement satisfaction.

However, hardware prototyping has a limitation in the number of iterations compared to software development due to cost constraints. Each iteration and test come with a cost that may increase the value of the project.

4. Prolonged Production Development

Prototyping is a quick and effective way of bringing the client’s idea to life. However, building a functional and workable prototype can be time-consuming. Before finalizing a design for manufacturing, prototypes get reviewed by the customers, and new suggestions or features get considered and implemented

After spending hours creating an accurate prototype that showcases the idea, making changes to prototypes is a tiresome task. Whether it is to make changes in the board's design or PCB layout, it has a ripple effect on the whole product design, causing a delay in the entire process and product development. Any hardware changes add cost to the project.

5. Unsteady Product

Innovation and idea creation always have a chance of failure associated with it. Mistakes like poor decision-making, excessive focus on a particular prototype, hurry to build prototypes, etc., results in an unsteady product

While creating a prototype within a short timeline, developers may make poor decisions, affecting the final product quality. Misunderstanding of the user’s objective or excessive focus on a product prototype with specific functionalities may lead to ignorance of other best alternatives and impact the end product quality.

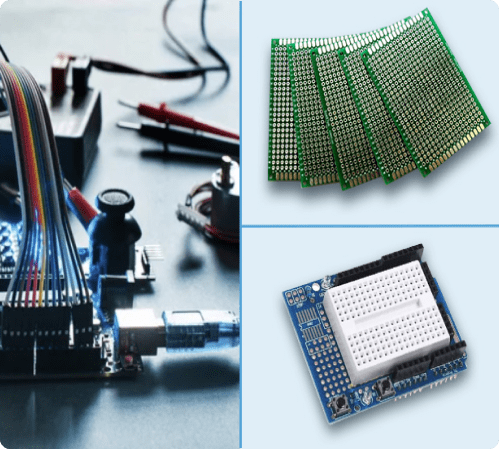

6. Interrupted Supply Chain Management

New product development requires fast prototyping and hardware requirements, like, electronic parts, breadboards, microcontroller chips, sensors, actuators, etc. A reliable, fast, and uninterrupted supply chain ensures prototyping and product development speed.

An efficient supply chain management is crucial to streamlining the product design and development phase

7. Time-consuming Testing

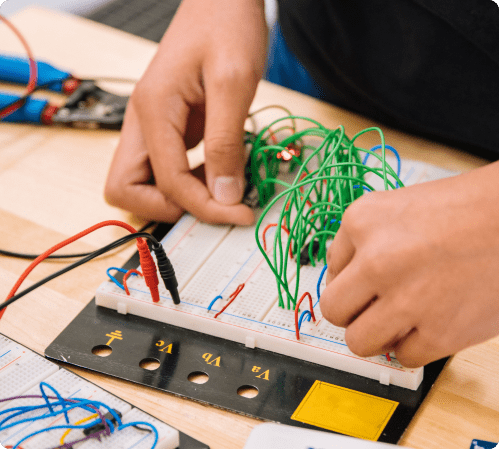

Prototype testing helps validate a design, identify issues in the design, refine ideas early in the product development process, get real-user feedback, and fix usability issues. Some strategic testing methods for early-stage hardware development are usability testing, material and finish testing, and key component testing

Usability testing is a comprehensive process essential to understanding how target users experience your product and verifying or falsifying the hypothesis. Material and finish testing ensure the perceived value and quality of hardware products. While testing key components, it is crucial to simulate real use conditions to check the feasibility of each component.

Thus, prototyping testing should be a comprehensive plan to ensure the design and final product feasibility.

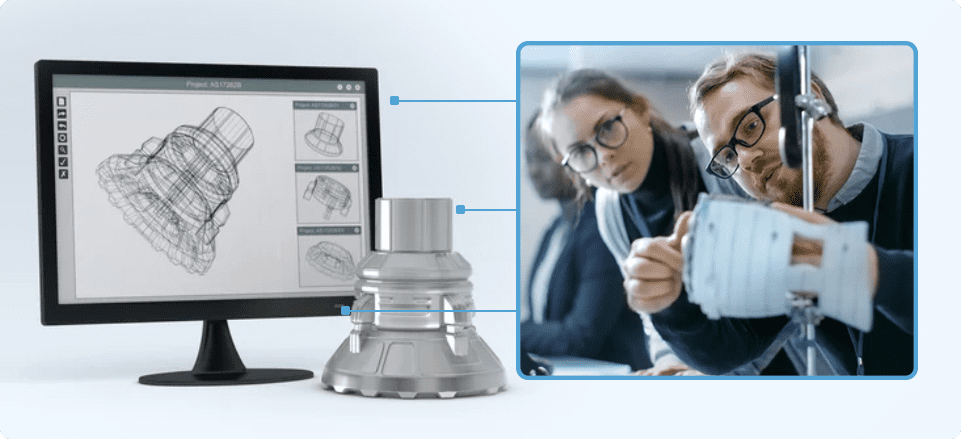

Hardware Prototyping – A Way to

Transform Your Idea into Reality

In this competitive environment, where the complexity of the embedded system is steadily rising, prototyping has become crucial to understanding customers' needs and creating a new market. A prototype helps convert an idea into reality, validate the idea, identify the risk of failure, streamline the design, and bring several cost benefits to an organization.

eLogicTech Edge, a pioneer in the engineering field, provides a comprehensive embedded system and IoT solution to industries across different sectors. Our hardware prototyping solutions help reduce the production cost, determine the initial cost, and provide value to the idea of funding. By considering several hidden costs associated with hardware prototyping, eLogicTech follows effective measures and steps, such as cooperative prototyping, parallel prototyping, product mockups, etc., to reduce prototyping cost and time.